The gossip of “texturgie” for the Year 2018:

creating new sensitive matters by combining textile textures and high technologies

(créer de nouvelles matières sensibles en combinant textures textiles et hautes technologies)

La minute de la texturgie n° 22 - novembre 2018

KnitCandela: 3D-knitted structure that serves as the primary shaping element for curved concrete shells

Employing knitted textiles in architectural applications cuts down on material, labour and waste, and simplifies the construction process for complex shapes.

The lower layer forms the visible ceiling – a designed surface with a colourful pattern. The upper layer contains sleeves for the cables of the formwork system and pockets for simple balloons, which, after the entire structure is coated in concrete, become hollow spaces that help save on materials and on weight. Manufacturing a formwork for such a geometrically complex structure using conventional methods would cost substantially more in both time and material, the researchers say.

KnitCandela (The formwork is made of a knitted textile), Photograph: Philippe Block

Solid growth for carbon fibre: a notable number of recent acquisitions

The global demand for carbon fibre will continue to enjoy a CAGR of 11.5% up to 2022, according to Michael Sauer of the German industry association Carbon Composites.

The industry’s expansion strategy, it was said, is mainly being driven by the carbon fibre producers, with horizontal diversification involving the broadening of product portfolios, as well as vertical integration. There have been a notable number of recent acquisitions in respect of the latter, including Toray’s acquisition of TenCate Advanced Composites, Kangde’s acquisition of SGL Kümpers, Toho’s purchase of Continental Structural Plastics, Hexcel buying Structil, and Mitsubishi acquiring Gemini Composites.

The world’s largest 3D printed structure made by Branch Technology from carbon fibre reinforced ABS

One goal: to recycle 100% of all textile waste

Within the framework of the Industry Research Group (IRG), a consortium consisting of companies along the textile value chain and the ITA is conducting application-oriented and industrially oriented basic research. In the target group of the IRG "Polymer Recycling", companies deal with the subject of recycling in the textile industry - from plant constructors to material, fibre and textile manufacturers to producers of end products and recyclers.

In the long term, textile waste, also consisting of mixed fibres (e.g. cotton and polyester), is to be recycled and extruded into high-quality yarns by using chemical recycling.

Polymer recycling, source: ITA RWTH Aachen University

La minute de la texturgie n° 21 - octobre 2018

Reflector warp knit plays key role in connecting the world

As a part of the Space-R-eflector project, The Institut für Textiltechnik Aachen (ITA) of RWTH Aachen University and its partner Large Space Structures GmbH (LSS) based out of Munich will develop advanced communication satellite systems. ITA’s role will primarily be focused on the development of the reflector surface mesh structure which is at the heart of these advanced communication satellite systems. Growing internet consumption requires advanced satellite reflectors to meet the high bandwidth and transmission needs.

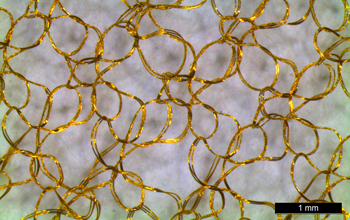

Microscopic image of a reflector warp knit fabricated at the ITA; source: ITA

To sew or to seal: expanding the toolbox

Virtually any fabric can be sewn, which isn’t necessarily the case when it comes to sealing. Take awnings, for example. Sewing will create holes in the fabric that could leak. In sealing, you’re relying on the integrity of the fabric. For example, if the coating fails, you could have a seam failure. Still, where you have very long seams, such as a tarp, then sealing is probably the way to go. But when there are complicated corners, or straps, webbing, D-rings or zippers around the perimeter of an item, or multiple layers of fabric, that’s when, in general, sewing is better.

Airtight hazmat suits manufactured by Vinyl Technology; Photo: Vinyl Technology Inc.

The movement of hands creates new shapes to cloth

For summer 2019, Issey Miyake designer Yoshiyuki Miyamae desired freshness and lightness highlighting the “traces of the hand”, as well as the importance of the human and of the artisan. The new flexible texture, named “Dough Dough”, appears on many pieces that you can twist and pleat infinitely changing the shape or length of clothes. Like you would style your hair differently according to your mood, the shape memory fabric allows you to change the shape of the garment by rolling up the collar, sleeve, or brim of hats.

Women's Spring/Summer 2019 Collection; Issey Miyake Inc.

La minute de la texturgie n° 20 - septembre 2018

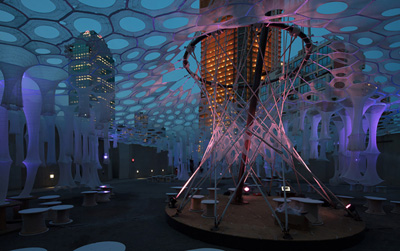

A fabric/light sculpture with something physical, visual and emotional

In the rotunda of the new Mississippi Civil Rights Museum the fabric/light sculpture This Little Light of Mine, a metaphor for the civil rights movement, is unlike any other, anywhere. Its message: Lights came into Mississippi. … From all over the United States, people came in, and they were lights.

The sculpture is in ambient mode most of the time, with gently moving lights and audio, with a show mode every half hour. Each blade has up to eight channels of lights, and each channel has at least 40 LED lights, scribbling a quick calculation of probably 10,000 lights, and those are individually controlled, almost like pixels.

This Little Light of Mine fabric sculpture, photo by Sherry Lucas

A polymer material that can change its structure in response to light

Researchers at Massachusetts Institute of Technology (MIT) have designed a polymer material that can change its structure in response to light, converting from a rigid substance to a softer one that can heal itself when damaged. The material consists of polymers attached to a light-sensitive molecule that can be used to alter the bonds formed within the material.

This approach overcomes the trade-off that usually occurs with self-healing materials, which is that they tend to be relatively structurally weak. In this case, the material can switch between the softer, self-healing state and a more rigid state.

A polymer that can reversibly switch; Image: Demin Liu/Molgraphics

Indian castor bean sustainability program a success to bio-based polymers

Arkema and BASF, along with castor oil firm Jayant Agro-Organics and the civil society organization Solidaridad, have wrapped up an initiative to put a sustainable castor oil supply chain in place in Gujarat, India. Leading chemical companies have empowered 1,019 Indian farmers.

The nylon 11 precursor 11-aminoundecanoic acid is derived from castor oil. Arkema is a leading supplier of bio-based high performance polymers derived from castor oil. Their flagship Rilsan® polyamide 11 resins and their Pebax® Rnew® elastomers are specified across the world in numerous applications.

Castor bean seeds; photo Jayant Agro Organics

La minute de la texturgie n° 19 - juin 2018

This amazing fabric can change its color on demand

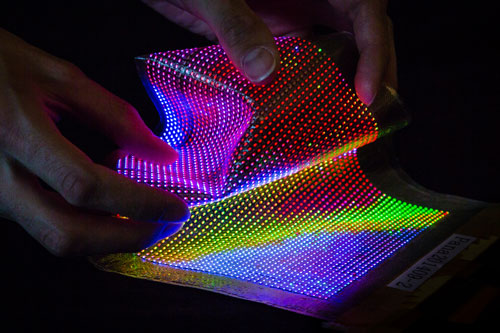

CREOL, the College of Optics and Photonics at the University of Central Florida (UCF), has produced the first-ever, active user-controlled colour-changing fabric which allows the user/wearer to change the colour or pattern of the fabric through smartphone. Each thread woven into the fabric incorporates within it a thin metal micro-wire. An electric current flows through the micro-wires, thus slightly raising the thread’s temperature. Special pigments embedded in the thread then respond to this modification of temperature by changing its colour.

ChroMorphous prototype, CREOL, University of Central Florida

Unique molecular tags from fibre to fabric to build trust and credibility

Unique molecular SigNature tags are the core technology ingredient of the Applied DNA Sciences’ family of security and authentication solutions. CertainT platform can be used to help assure authenticity, origin, traceability, as well as the quality of products. The system is also being used with man-made fibres to tag in large scale. It brings forensic traceability from fibre to fabric to supply chains through tagging, testing and tracking the product itself.

CertainT platform of Tag, courtesy of Applied DNA Sciences

Transformation of the textile industry to make it value-added and high-tech

Advanced Functional Fabrics of America (AFFOA) is partnering with MIT-Venture Mentoring Service to launch the Advanced Fabric Entrepreneurship Program. AFFOA’s mission is to catalyze a domestic manufacturing-based revolution, converting traditional fibers, yarns and textiles into sophisticated, integrated and networked devices and systems, facilitating the transformation of the textile industry to make it value-added and high-tech.

Turning clothing into information displays, developed by Holst Centre, imec and CSMT

La minute de la texturgie n° 18 - mai 2018

A fibre sculpture for the cycles of time

Madrid’s historic Plaza Mayor celebrated its 400th anniversary in February 2018. In honor of the occasion, the city of Madrid, Spain, commissioned an original sculpture by American artist Janet Echelman who created an installation—1.78 Madrid—that explored the cycles of time. It was the newest edition to her “Earth Time Series,” which she began in 2010 and has exhibited in different iterations in cities across the globe.

The installation was composed of layers of a highly engineered fiber 15 times stronger than steel by weight. Echelman used 77 miles of colorful extruded fiber, braided it and shaped it with 600,000 knots. The result was a vibrant, voluminous form that changed shape with wind and weather.

A hopeful trajectory of humanity, photo: Joao Ferrand, Studio Echelman.

New smart ink produces 3D objects able to change shape and color

Researchers at Dartmouth College have developed a smart ink that turns 3D-printed structures into objects that can change shape and color. This technique gives life to 3D-printed objects and promises to add even more functionality to 3D printing. It could pave the way for a new generation of printed material.

The new process allows designers to retain specific molecular alignments and functions in a material. Researchers expect the process to result in a new class of macroscale 3D printed objects that can be used to deliver medicine or produce high resolution bone replacements.

3D-printed object composed of hydrogel (G1) changing size after printing, photo: Chenfeng Ke

First recombinant spider silk cocoons from hybrid transgenic silkworms

Kraig Biocraft Laboratories, a leading developer of spider silk-based fibres, has successfully produced the first recombinant spider silk cocoons from the new line of hybrid transgenic silkworms recently created at its Michigan production and research facility. The first-generation cocoons from this hybrid cross have exceeded the company’s expectations with some cocoons nearly twice as large as the original spider silk line cocoons.

The company will deliver ballistic shoot packs constructed from its proprietary Dragon Silk material for performance testing.

Kraig Biocraft Laboratories, Inc. Recombinant Spider Silk Technology

La minute de la texturgie n° 17 - avril 2018

Space, sound and mood: what fabric offers most is its versatility

The use of fabric to create an atmosphere in a space is a wise choice. It can be changed without much fuss and without moving existing structures. Fabric can be tight and hard-edged, or loose and soft. It can span large areas seamlessly, or be used as small accent elements. It can be static and permanent, or billowy and ephemeral. It can have texture and depth, or be smooth and monolithic. It can carry inks and dyes, or be used as a reflective or projection surface. New technological developments have enabled the design of fine sheer materials that allow light and visual transparency while boasting serious acoustical properties, inviting interior designers to rethink the concept of a private space.

Sheer mesh fabrics designed for translucency and controlled sound, photo: Designtex

Scientists create electrically conductive nonwovens suitable for clothing

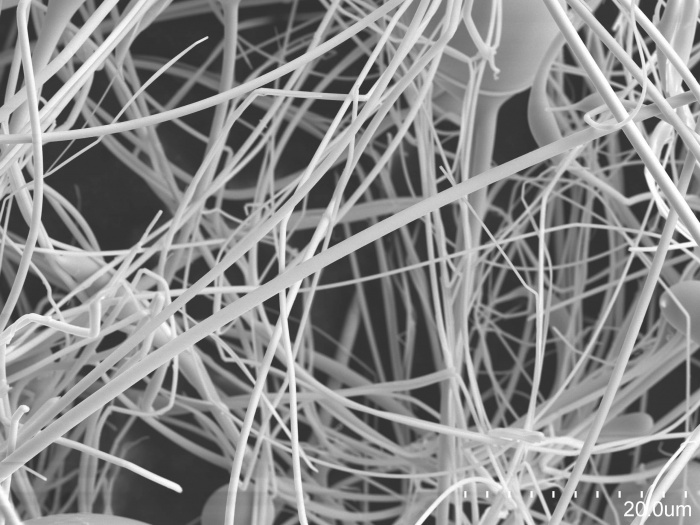

Prof. Dr. Andreas Greiner’s team of researchers at the University of Bayreuth and their Chinese partners have succeeded in producing electrically conductive nonwovens suitable for clothing. The materials are flexible, and thus adapt to movements and changes in posture. In addition, they are air-permeable, meaning they do not interfere with the natural breathing of the skin.

In contrast to common methods of production, metal wires were not inserted into finished textiles. Rather, the scientists modified classical electro-spinning, which has been used to produce nonwovens for many years: short electro-spun polymer fibres and small amounts of tiny silver wires with a diameter of only 80 nanometres are mixed in a liquid. Afterwards, they are filtered, dried, and briefly heated up. If the composition is right, the resulting nonwoven material exhibits a very high degree of electrical conductivity.

Thin fibres from which nonwoven materials are formed, source: Christian Wißler

Polymers can guide 3D printing of nanoscale metal structures

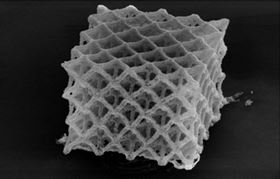

For the first time, it is now possible to create complex nanoscale metal structures using 3D printing, thanks to a new technique developed by scientists at the California Institute of Technology (Caltech). The process, once scaled up, could be used for a wide variety of applications, from building tiny medical implants to creating 3D logic circuits on computer chips to engineering ultralightweight aircraft components. It also opens the door to the creation of a new class of materials with unusual properties based on their internal structure.

A lattice of 3D printed nickel; Image: Greer Lab

La minute de la texturgie n° 16 - février 2018

A New Frontier: The Interconnection of Energy Storage

Energy storage promises is vitally important in accelerating integration of all types of distributed energy resources, or DERs. Scientists are bridging gaps in current technologies, inventing new ways to improve energy storage performance, designing new materials and storage architectures. The use of software and cognitive learning is necessary to assess and optimise the use of battery storage to really utilize the energy consumption on the site to maximise revenue streams. Composites will score highly in both stationary and mobile storage systems due to their durability, chemical resistance and lightweight potential.

Energy storage; courtesy of Texas Sierra Club

The quest to produce a bio-based nylon 6,6 polymer has now come to fruition

Caprolactam is traditionally synthetized from oil-derived cyclohexanone. The vast majority is used to make nylon-based products including carpets and apparel. Genomatica and Italy-based polyamide producer Aquafil announced their collaboration in the development of sugar-based caprolactam, a key raw material in the production of polyamide 6.

The performance of the nylon end products will be fully comparable to those made from crude oil-derived caprolactam and will not require any machine or process adjustments by the nylon supply chain. The companies claim will play a key role in slashing environmental impacts from the nylon supply chain.

Undergarments made with nylon fibers 1963; courtesy of genlbee/Flickr

Fabrics that store information without electronics

Allen School researchers invent smart fabric that stores data without electronics. To produce their smart textiles, the researchers used a conventional sewing machine to embroider the conductive thread onto fabric. They then manipulated the fabric, using a magnet to align the poles in a positive or negative direction to correspond with ones and zeros. The data encoded in the fabric can be read by a magnetometer — an inexpensive device that is built into most smartphones.

The researchers enabled gesture recognition by sewing the magnetized thread into the fingers of a glove. The phone was able to detect six commonly used interactive gestures with 90 percent accuracy.

Magnetized thread into the fingers of a glove; Dennis Wise/University of Washington

La minute de la texturgie n° 15 - janvier 2018

Today knitting plays a larger role to create living spaces

Today, knitting plays a larger and larger role because it allows a higher level of detail and more flexibility in the end product. The textile can be knitted directly into the desired shape, while considering necessary functionality in the pattern at the same time, without requiring additional work.

The Museum of Modern Art of New York (MoMA) started the Young Architects Program in cooperation with MoMA PS1. This year's winner of the competition is Jenny Sabin with her Lumen project. The designer describes her work as "knitted light" because it consists almost entirely of textiles that illuminate under certain conditions.

Project Lumen, 2017 award MoMA PS1; courtesy of Jenny Sabin Studio

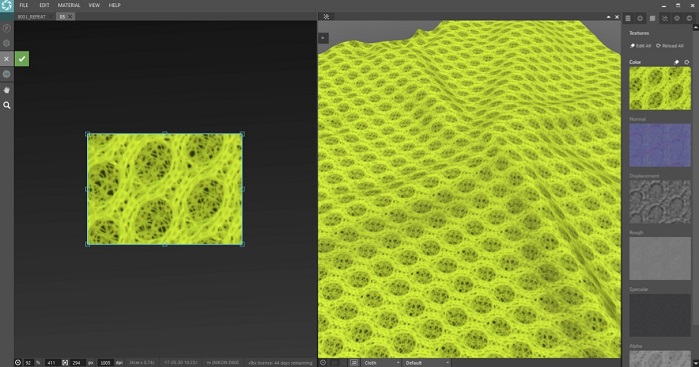

3D garments: how to to ensure consistency between virtual prototypes and physical end products?

Despite recent advances in 3D software innovation, many end-users still argue that the industry is nowhere near ready to replace physical samples with virtual ones.

Due to the complex behaviour of materials, it is important to improve input parameters, such as bend, shear, stretch, weight, friction and thickness, and measure what happens when the materials touch the body to mimic actual fabric and garment behaviour. Standardisation of different testing methods and interoperability between 3D simulation software were suggested as potential solutions.

Scanned material ready for use © Vizoo GmbH

Lightweight carbon fibre construction enables truly inspirational structures

The roof of the Steve Jobs Theatre is the largest self-supporting CFRP roof ever built. The entrance to the Steve Jobs theatre is through a spectacular glass walled pavilion topped by a thin carbon fibre roof, which is 155 feet in diameter, which appears to float effortlessly above the ground as it is supported only by the curved glass walls of the pavilion. The carbon fibre structure had to be exceptionally light and stiff to span 130 feet between supports, as well as being capable of withstanding wind and seismic loading on the roof and providing lateral support to the glass façade.

Roof of Apple headquarters in Cupertino, CA, © Premier Composite Technologies (PCT)