The gossip of “texturgie” for the Year 2021:

creating new sensitive matters by combining textile textures and high technologies

(créer de nouvelles matières sensibles en combinant textures textiles et hautes technologies)

La minute de la texturgie n° 45 - November 2021

Innovative fabric enables digital battery-free communication between wearers, nearby devices

Researchers in UCI’s Henry Samueli School of Engineering integrated advanced metamaterials into flexible textiles to create a system capable of battery-free communication between articles of clothing and nearby devices.

The near-field communications protocol has enabled the growth in applications such as wireless device charging and powering of battery-free sensors, but a drawback of NFC has been its limited range of only a couple of inches. The UCI researchers extended the signal reach to more than 4 feet using passive magnetic metamaterials based on etched foils of copper and aluminum.

Innovative fabric enables digital communication between wearers; © Steve Zylius / UCI

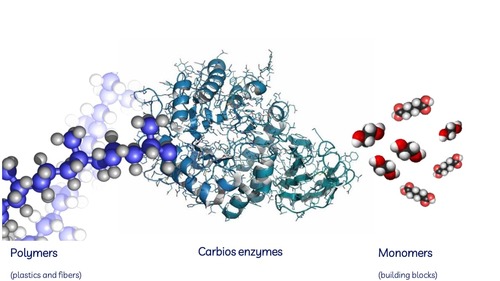

Carbios launches industrial demonstration plant for its unique enzymatic recycling technology

Carbios, a French company pioneering new enzymatic solutions to reinvent the lifecycle of plastic and textile polymers, announced the official opening and launch of an industrial demonstration plant operating with its enzymatic recycling technology, C-ZYME®, which was installed on the Cataroux site in Clermont-Ferrand.

Unlike traditional methods, Carbios’ breakthrough enables unlimited recycling of all sorts of PET waste (clear, colored, opaque, complex plastics, polyester textiles) as well as the production of 100% recycled and 100% recyclable PET goods that maintain their virgin quality throughout the process.

enzymatic recycling process, C-ZYME®; © Carbios

Evrnu expedites global deployment of NuCycl technologies

Evrnu, based in Seattle, Washington, has raised $15 million to scale and meet the surging demand for its fibre regeneration platform, NuCycl. The strategic financing will be used to expand Evrnu’s facilities and operations in South Carolina and service high volumes of NuCycl fibres to the fashion industry.

Evrnu’s NuCycl platform depolymerizes textile waste and repolymerizes it fibres that are on par or higher quality than the inputs and can be recycled multiple times.

Higher quality NuCycl fibres; © Evrnu

La minute de la texturgie n° 44 - September 2021

Engineers create a programmable fiber

MIT researchers have created the first fiber with digital capabilities, able to sense, store, analyze, and infer activity after being sewn into a shirt. In a first, the digital fiber contains memory, temperature sensors, and a trained neural network program for inferring physical activity.

Until now, electronic fibers have been analog — carrying a continuous electrical signal. This work adds a new information content dimension to textiles and allows fabrics to be programmed literally.

Intelligent digital fibre; © Actu IA

Arkema to start up new bio-based nylon 11 plant in Singapore

This plant on Jurong Island, for which production will be 100-percent-derived from renewable castor beans, represents a 50-percent increase in Arkema’s global polyamide 11 capacity.

With this ambitious project announced in 2017, Arkema is delivering on its strong commitment to Specialty Materials and the bio-based polyamide 11 chain. When complete, this will represent the biggest integrated bio-factory in the world dedicated to high performance polymers.

Arkema to begin production at its new biobased polyamide 11 biorefinery; © BioRefineries Blog

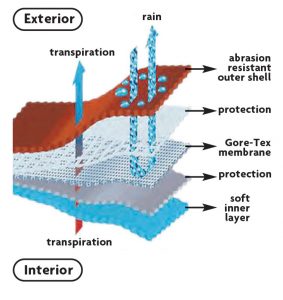

Dying, printing & finishing: PFAS regulation and textile perspective

Despite the textile industry’s limited use of PFAS materials, future regulation may impact producers of performance fabrics. The primary PFAS chemicals used in textiles include polytetrafluoroethylene (PTFE) and short-chain fluorinated polymers known as C6 or C4 chemistries. PTFE can serve as a waterproof breathable membrane, and the C6 reduces the surface energy of the uppermost layer, imparting water and oil repellency. Non-fluorinated chemistries are available as supplements or replacements to the PFAS-containing materials, but they tend to not perform as well...

The scope of PFAS regulation extends well beyond textiles. As regulators and consumer groups start to realize PFAS is essential to industries tied to national security — such as semiconductors and microchips — and renewable energy, including photovoltaics and rechargeable batteries, there has been a push, particularly in Europe and by U.S. states, to distinguish between essential and non-essential end-uses. Their goal is to eliminate non-essential end-uses.

PTFE waterproof breathable membrane; © Textile World

La minute de la texturgie n° 43 - June 2021

New jacquard weaving technology to seamlessly integrate functional and design weaves

ProWeave can help manufacturers pinpoint the physical characteristics, functional zones and visual patterns they want to achieve on a performance fabric. Creating different elasticity, tenacity and abrasion zones within the same weave, ProWeave is a patented new jacquard weaving technology developed by Texon at its plant in Prato, Italy.

There is a real curiosity about a technology that can free designers from conventional fabric restraints...

and perhaps a new method to have clothes that are built to last?

Patented jacquard weaving technology ProWeave; © Texon

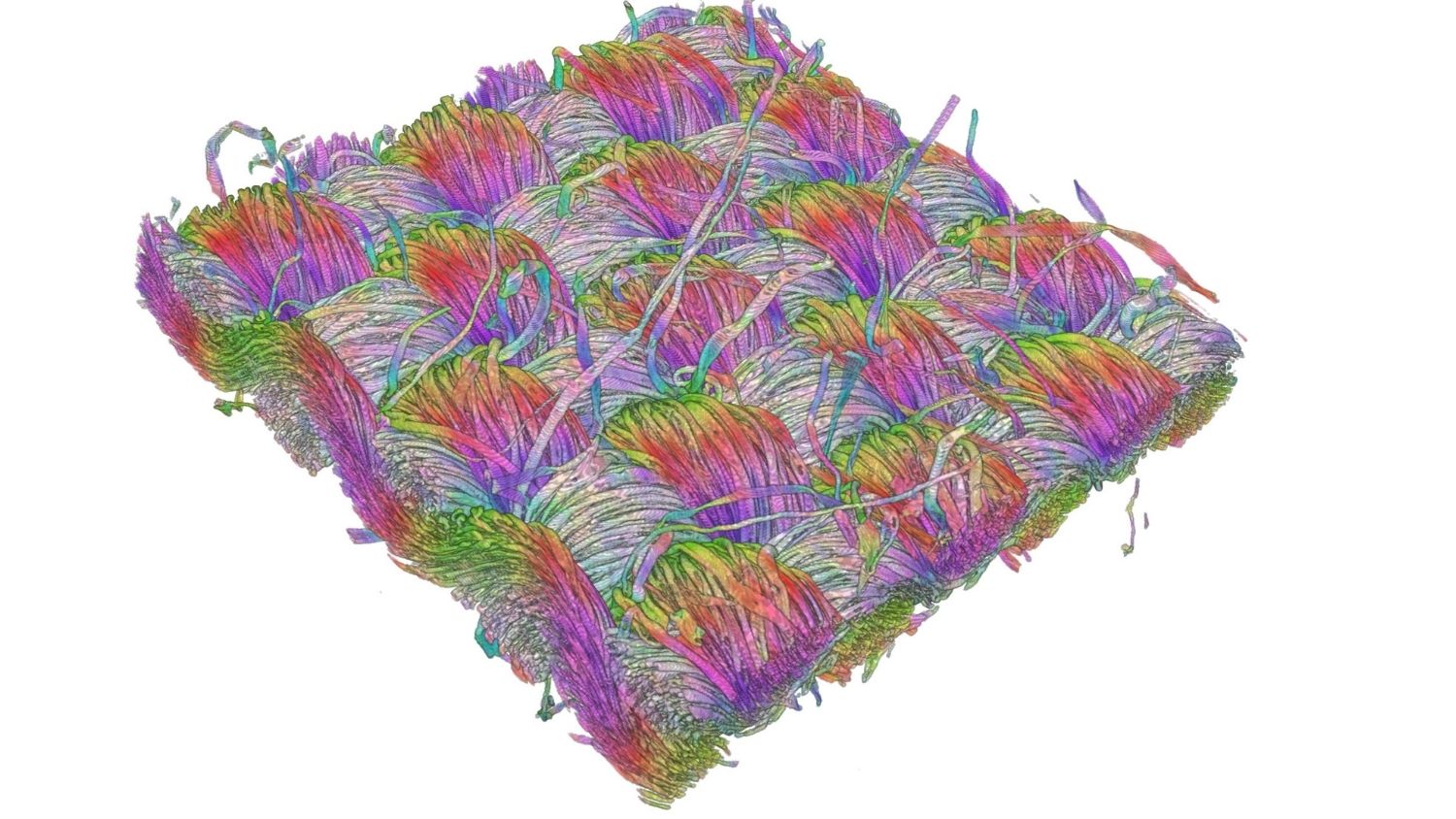

A new way to measure fabric friction using 3D imaging

To quantify exactly how itchy a wool sweater might be when worn directly against the skin, North Carolina State University researchers developed a method of measuring fabric’s roughness using 3D imaging. They used an imaging tool – X-ray micro-computed tomography – to take 3D images of the surface of fabric in order to calculate the surface geometry, and measure the impact on friction. Their method can quantify skin-textile interface at a microscale without destroying the fabric.

A woven fabric surface analysis image, NC State Analytical Instrumentation Facility. Credit: Ruksana Baby.

Circular economy also has to be about keeping the garment going for longer

A misinterpretation of the circular economy is to focus just on end-of-life – but it also has to be about keeping the garment going for longer. It’s vital to ensure products are long-lasting. Recycled, recyclable and reusable remain the triple bottom line in sustainability, but the tricky part is ensuring performance too. Mono materials are great for recycling, but it has been calculated that end-of-life is responsible for just 10% of a garment’s carbon footprint. Extending the life of a garment for one more season can make a positive 25% improvement.

How to buy clothes that are built to last?

La minute de la texturgie n° 42 - March 2021

The textile dyeing industry is experiencing a global skills gap

77% of textile coloration professionals believe there is a widening skills gap in the dyeing industry, with 53% of agreeing this is now at crisis point, according to SDC (Society of Dyers and Colourists) survey.

Findings state that a third of global employers involved in dyeing and finishing are unable to recruit the talent that they need. Reasons for this were cited as young people having negative perceptions of the industry, or wanting to be designers rather than dyers, alongside a lack of knowledge of the chemistry behind the processes, as well as poorly promoted opportunities in dyeing.

Textile dyes & auxiliaries; © Grupo ADI

Dyeing or coating textile with NIR technology

New minimum application, digital spray or rotor application textile dyeing and coating technologies claim major resource savings in terms of water, energy and chemicals. But the technology of Adphos, based in Heufeld near Munich, however, goes much further.

In the adphosNIR wavelength range, most plastics and synthetic fibres have a high radiation transparency. The beams immediately penetrate deeply, and heating is performed rapidly and evenly with extremely short processing times. There is also a big reduction in energy consumption because the system does not have to be preheated. In addition, it takes up a lot less space.

adphosNIR®-technology; Adphos Group

Tulle-like DefeXtiles 3D printed: a new quasi-textile

MIT Media Lab graduate student Jack Forman used a standard, inexpensive 3D printer to produce sheets and complex 3D geometries with a woven-like structure based on the “glob-stretch” pattern produced by under-extrusion.

Forman works in the Tangible Media research group with Professor Hiroshi Ishii. “We envision that the materials of the future will be dynamic and computational,” says Ishii. “We call it ‘Radical Atoms.’ DefeXtiles is an excellent example of Radical Atoms, a programmable matter that emulates the properties of existing materials and goes beyond. We can touch, feel, wear, and print them.”

La minute de la texturgie n° 41 - January 2021

Cellulose Fibre Innovation of the Year: the fastest growing fiber group in textiles

For the first time ever, the innovation award “Cellulose Fibre Innovation of the Year” will be granted to the innovative cellulose fiber industry for the development of new technologies and applications. Cellulose fibers are the fastest growing fiber group in textiles, the largest investment sector in the bio-based economy.

The “2nd International Conference on Cellulose Fibres” will cover the entire value chain from lignocellulosic feedstock, dissolving pulp, cellulose fibers — such as rayon, viscose, Modal, lyocell or new developments — to a wide range of applications, woven textiles (clothing) and non-wovens (wipes and technical applications). All these sectors have significantly gained momentum over the last few years.

Cellulose Foam by Stora Enso *Formerly known as Cellufoam

A process for reusing silk textiles and use it for high-performance thermal insulation

The practice of using recycled materials from other industries, such as post-consumer PET bottles, has been common practice in the textile industry for years. Freudenberg and Ratti are now re-using silk textiles from their own industry, the clothing industry, in a jointly developed process.

Airlaid technology plays a key role in the re-use of silk textiles, enabling Freudenberg to produce waddings with a three-dimensional structure from this material. This leads to excellent thermal insulation properties combined with exceptional breathability.

Silk textiles reused in high-performance insulation; Pic: Freudenberg

Call for action on textile wet processing

Water is crucial in textile production. Wet processing in particular – which involves bleaching, dyeing and printing fabrics – is heavily reliant on clean freshwater. It is often difficult to link the fashion brands to the wet processors causing harm.

Planet Tracker layers wet processing factory geolocation data and water risk scores. Critically, for the 740 publicly listed companies directly involved in wet processing activities identified in Planet Tracker’s report, the majority of their factories are concentrated in emerging markets with high water stress (principally India, Pakistan and China), and, consequently, subject to significant water risk.